A team of scientists at NASA have blended the essence of fashion and engineering to produce a new fabric for use in space.

These fabrics can be used for antennas and other deployable devices. This fabric material is foldable and changes its shape quickly. They can also help shield a spacecraft from meteorites. Other uses of this fabric include, astronaut spacesuits, capturing objects on the surface of another planet and also as an insulating material for spacecrafts.

Raul Polit Casillas, one of the team members and a systems engineer at NASA-JPL grew up around fabrics. Along with his colleagues, he designed prototypes of the fabric that look like chain mail, with small silver squares strung together.

Credits: NASA/JPL-Caltech

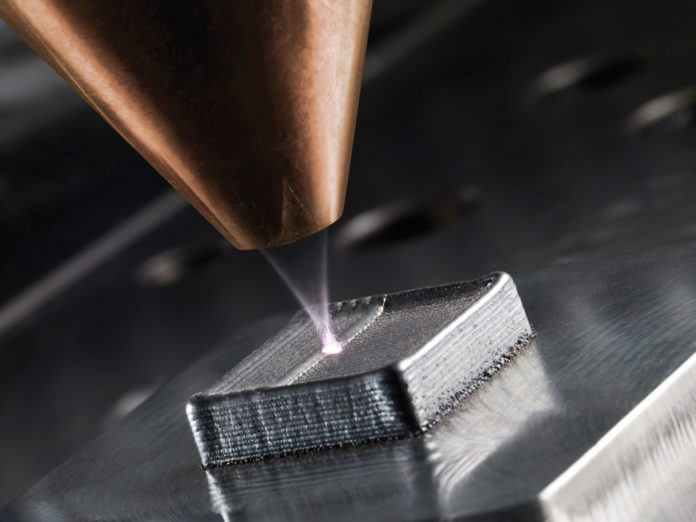

Another interesting fact about these prototypes is that they were not sewn by hand. Rather Raul and his team “printed” and created in one piece with advanced technologies.

According to the space agency, a technique called additive manufacturing is necessary to make such fabrics. This technique is a broad scale 3-d printing. Unlike the usual manufacturing techniques, where-in they weld the parts together, additive manufacturing deposits material in layers to build up the desired object. This reduces the cost and also increases the ability to create unique materials.

Credits: NASA/JPL-Caltech

The space fabrics have four essential functions. This includes reflectivity, passive heat management, foldability and also tensile strength. One side of the fabric reflects light, while the other absorbs it. This, thereby acts as a means of thermal control. It can fold and adapt to shapes while still being able to sustain the force of pulling on it.

This indeed is a revolutionary concept. The new fabric has now paved way for new techniques in spacecraft engineering. Instead of assembling something with dozens of parts, where there could be multiple errors, one can create the spacecraft of the future as a “whole cloth” . And also with added functions, it will prove to be a great breakthrough in space science.